Recently my cousin sent me a text message with some pretty alarming and exciting photos and videos.

Yeah, that’s right… the motherfucker made his own sous vide machine, cooked up some filets to medium rare, and then seared them the fuck off in a cast iron skillet to get some texture on the edges.

What exactly is a sous vide machine, for you non-food nerds? The words translated from French mean “under vacuum.” It is essentially a hot tub for meat. How it works: you place vacuum sealed meats into the water bath and leave them there until the meat comes up to the proper temperature, which is set and regulated with a water heater and temperature controller. You can’t overcook the meat! You get perfect medium rare shit every time, evenly cooked through and through.

As you can imagine, I was flipping out at what my cousin had achieved. I browsed some DIY sous vide instructional websites a few years back when I was living in a house on Long Island, but it seemed like a ton of effort. I thought to myself, “I’ll just get a real-deal machine someday.” But once I saw these things from my cousin, I knew it was time to pull the trigger.

Lucky for me, my cousin is super handy and craftsmanlike when it comes to stuff like this, and he has access to a bunch of great tools like dremels and drill presses.

A flurry of texts immediately ensued. It’d be fun to build one together, I thought. THIS LINK is the instructional we worked from. My cousin ordered a bunch of the materials online…

I pulled my cooler out of the closet, which would serve as the main cooking vessel or “hot tub” (and it saved me some bucks for not having to buy a plastic tub).

and I ordered a vacuum sealer via Amazon Prime…

I also nabbed a blow torch, a can of propane, and a Searzall, because I want to flame that shit sometimes instead of finishing in a pan. Plus, this works great if I ever do fish – the skin… oh maaaaan it gets crispy…

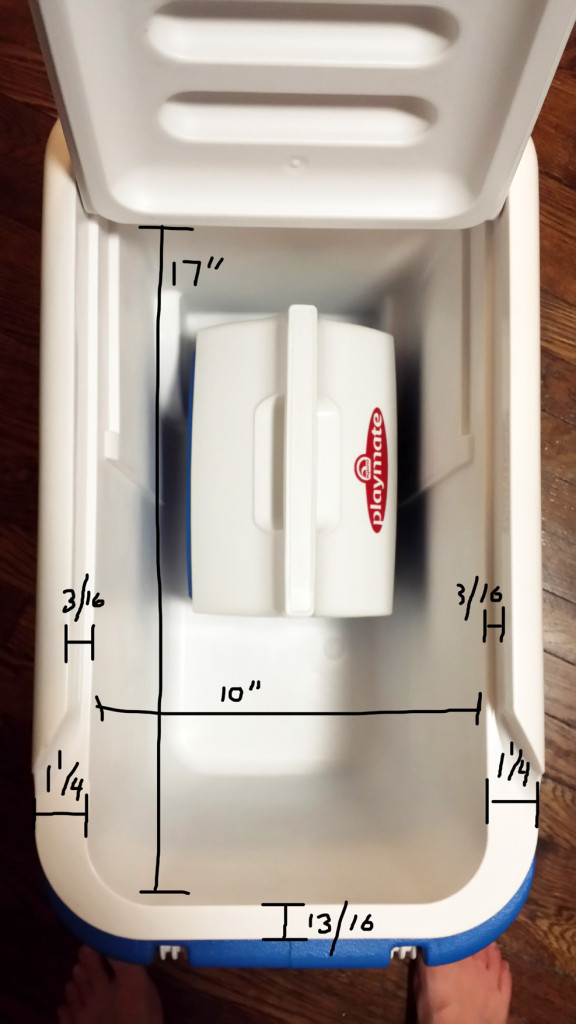

I sent the dimensions of my cooler lid area to my cousin:

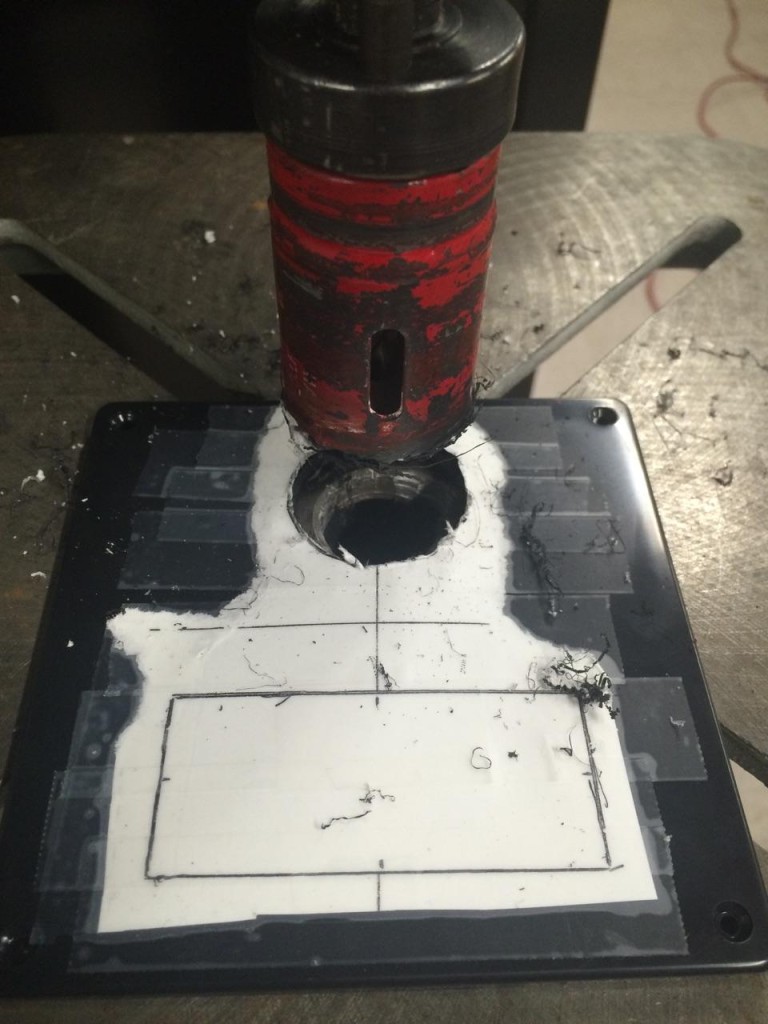

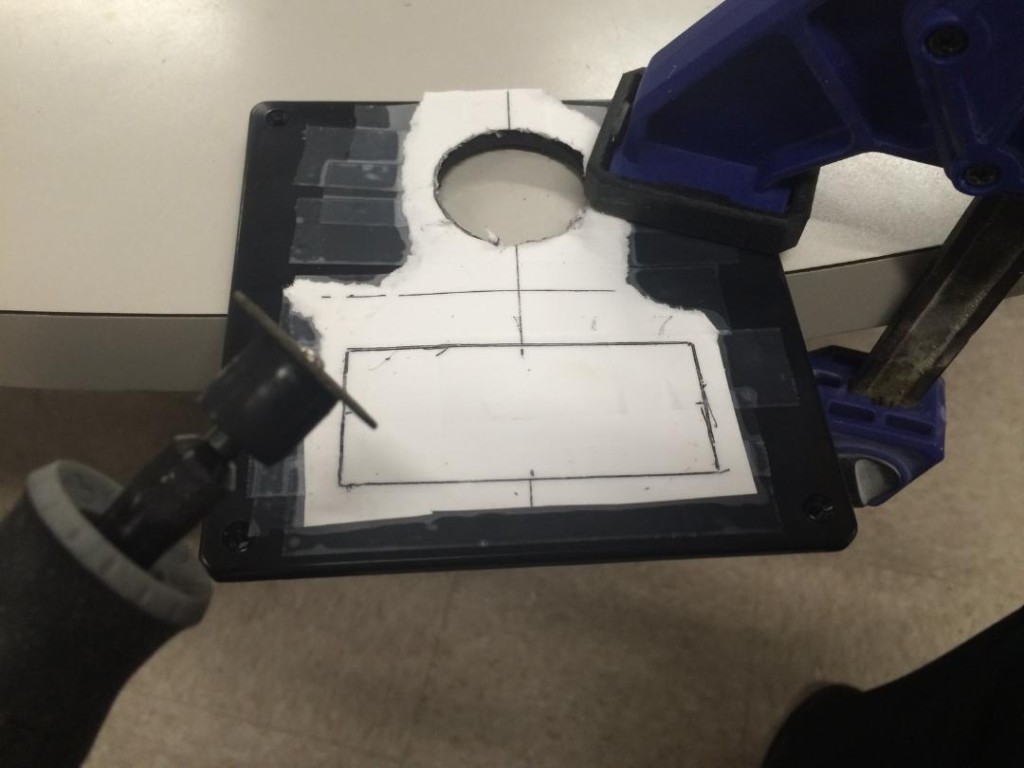

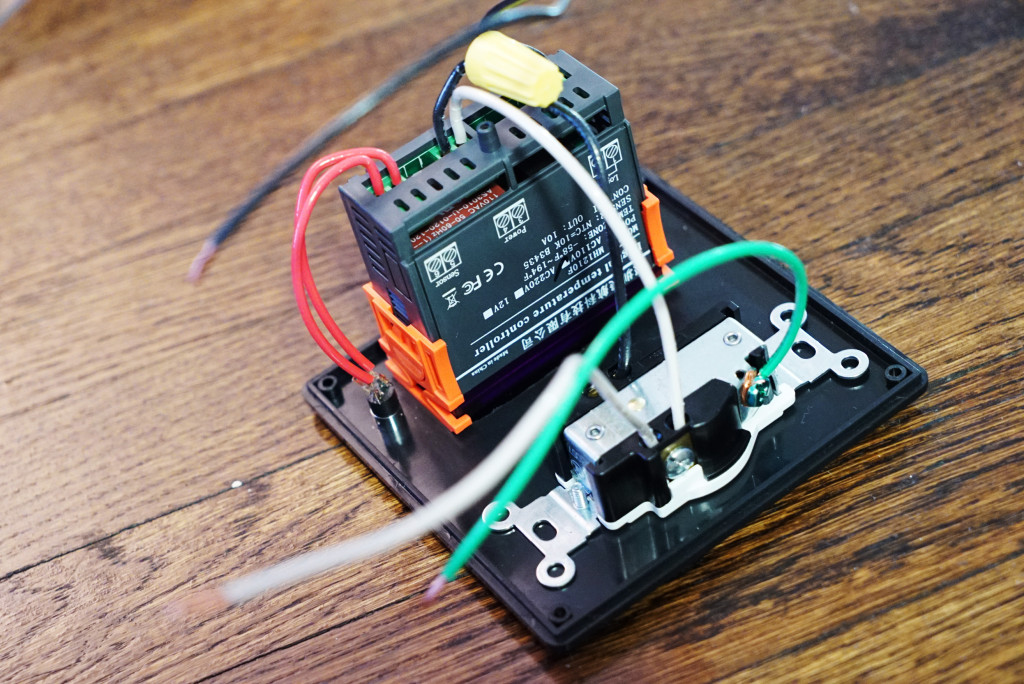

He used this to figure out how to cut the plexi down to size to serve as the top portion that suspends the water heater in position. He also built the temperature control housing, and wired the power supply for the temperature control unit and heater probe (thermometer).

I was initially concerned that the hinged top of my cooler wouldn’t close properly with the plexi in place. It turns out that closing the top tight isn’t too big of a problem when you’re using a nicely insulated vessel like a cooler. Also, we dropped the plexi to a lower lip within the cooler, so the thing closes nicely now:

Then you suction this to one of the walls. Essentially this is a water circulator. It keeps the water swirling around so that there are no warm or cold spots within the bath, which makes for a nice even cooking temperature.

BOOM! I can’t wait to fire this fucker up. I’m going to pick up some fish and beef right the fuck now.